For 20 years bf1systems and ka sensors have provided high accuracy, durable force measurement solutions to the motorsport, automotive and sports industries.

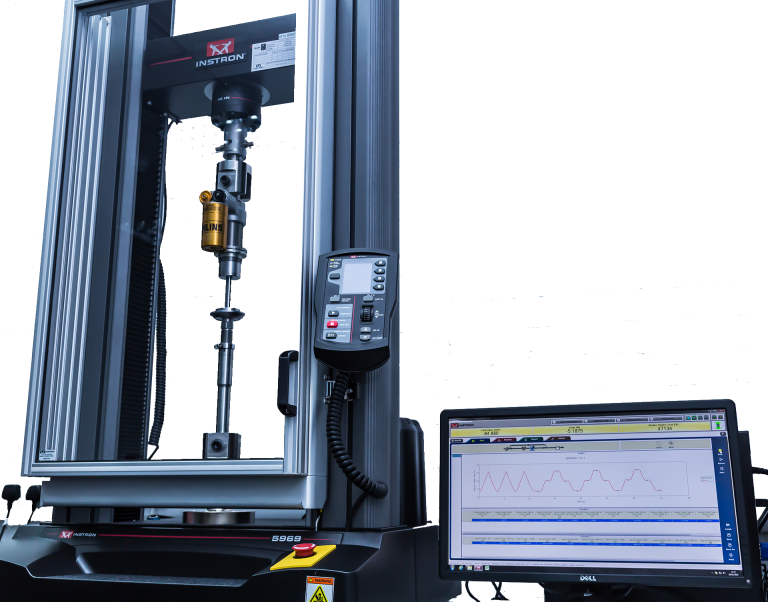

Accuracy, reliability and repeatability are fundamental to any force measurement part, and are the key considerations for any force measurement component that we design, produce or work on.

Whether you require one-offs, small, medium or large production runs, we can design and produce a solution to suit your application, ensuring the components give you the highest quality of data.

With a dedicated force measurement design team, production technicians, and a specially built calibration laboratory, we are equipped to take your component from concept to reality in the shortest possible time.

bf1systems provides a wide range of suspension force measurement components, including damper loadcells, pushrod and pullrod loadcells, spring top hat loadcells, tie rod loadcells and bump stop loadcells.

A wide range of components to suit different series’ are available off the shelf, and custom components can also be designed to accommodate customer requests.

All force measurement products utilise a strain gauge installation, along with a bf1systems amplifier.

Download our IndyCar pushrod top datasheet:

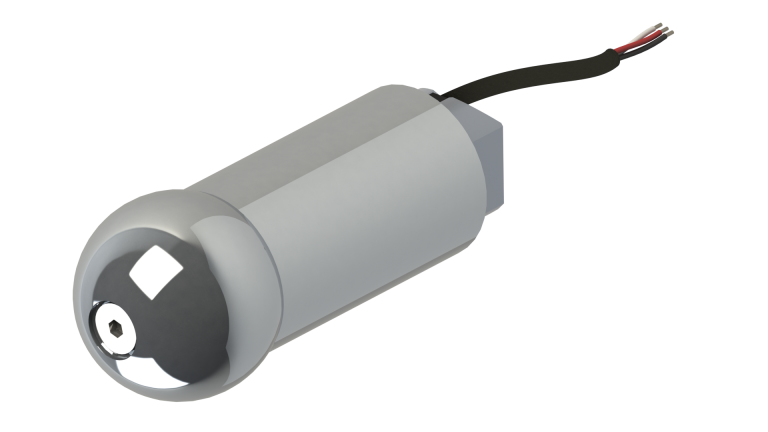

The GSS Series of Miniature Load Cells are designed for the detection and measurement of tension and compression forces in Gear Shift Application.

Construction is stainless steel with a built-in amplifier, allowing for a very simple installation with only a 3 wire connection needed. Mechanical mounting is via M6 or M8 threads.

The output signal is proportional to the amount of force applied and is linear 0.5 to 4.5V which can be connected to most common ECU’s. The typical application is for use such as: Flat Shift, Quickshifter, Torque Cut, Ignition Cut and Clutch-free Gearshift on race vehicles.

The Load Cells are generally installed into the actuator rod or cable on sequential gearboxes.

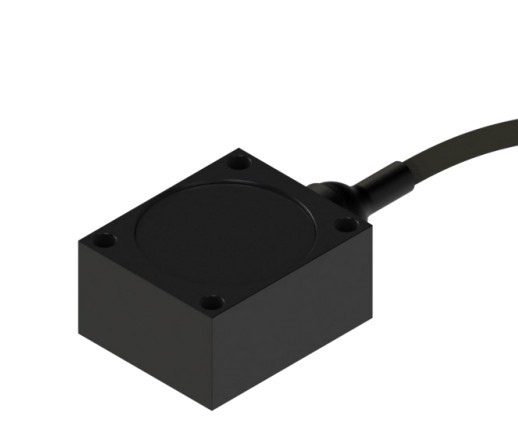

The GST Series of Gear Lever Load Cells are designed for the detection and measurement of driver input forces on a sequential gearbox. The measured signal is used within the vehicles ECU to control the gear change strategy.

The output signal is a linear 0.5 to 4.5V and is proportional to the amount of force applied.

Installation is a simple M10 x 1.5 thread or a straight 12.7mm (Quaife type) lever. Construction is aluminium with a built-in amplifier. The supply and signal are compatible with all standard ECUs used in motorsport.

The load cell is supplied from stock without a cover. Two optional covers of either aluminium or nylon are also available from stock, or the user can customise their own cover and fix with a supplied M5 screw.

The typical application is for use as: Flat Shift, Quickshifter, Torque Cut, Ignition Cut and Clutch-free Gearshift on race vehicles.

The KAFT Series of High Bandwidth Miniature Accelerometers offer a compact and robust

solution for the motorsports and automotive testing industry.

The sensor offers 2 or 3 Axis of measurement with integral signal conditioning to give a

standard signal of 0.5 to 4.5V; ideal for most data acquisition systems.

© 2025 bf1systems ltd. | Registered Company No 2902036 | VAT No. GB 751 0890 38.

Registered Office: Technical Centre, Owen Road, Diss, Norfolk, IP22 4ER, United Kingdom