With in-house design, manufacture and calibration of a wide range of pressure transducers, ka sensors are able to offer a wide range of both pressure sensors to suit a wide range of applications and budgets.

Our pressure sensors have been designed to work in the harshest of applications, such as being mounted directly to master cylinders on Le Mans winning race cars, on braking systems for rail locomotives, through to fuel systems on UAVs. Our experience of these harsh applications means reliability and quality is guaranteed, no matter where you want to use these parts.

We are aware that no two applications are the same, and customers are looking for sensors that not only meet their technical needs, but also commercially make sense.

For this reason we have created a range of pressure and combined pressure / temperature sensors to suit a variety of specifications and price points.

Typical applications for our pressure sensors include:

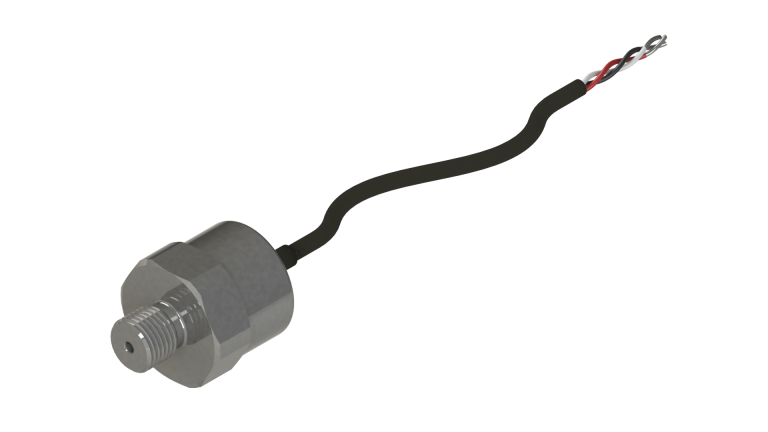

The ASL Series of Standard Pressure Transducers have been designed for the detection of fluid and air pressures in demanding motorsport and automotive applications; ideal for high precision data acquisition or control systems. These transducers can be installed directly onto vehicles, or as part of a test stand or dyno.

Offering a high level of reliability and endurance, the ASL Series is protected against the high vibration, shock and high temperatures found in motorsport. With a modular construction and a programmable amplifier, this provides a large stock available of standard parts for fast delivery.

Pressure ranges are available between 2 to 200 Bar in either Absolute or Sealed Gauge reference, with an optional pressure port snubber to assist with filtering pressure spikes.

Industry standard 3-wire electrical connections allow configuration with most common ECU’s and data logging systems.

The ASLA Series of Lightweight Standard Pressure Transducers have been designed for air box or boost pressures in demanding motorsport and automotive applications; ideal for high precision data acquisition or control systems. These transducers can be installed directly onto vehicles, or as part of a test stand or dyno.

Offering a high level of reliability and endurance the ASLA is protected against the high vibration, shock and high temperatures found in motorsport. With a modular construction and programmable amplifier, this provides a fast delivery time for standard configurations.

The ASLAB Series of Lightweight Standard Pressure Transducers have been designed for air box or boost pressures in demanding motorsport and automotive applications; ideal for high precision data acquisition or control systems. These transducers can be installed directly onto vehicles, or as part of a test stand or dyno.

Offering a high level of reliability and endurance the ASLAB is protected against the high vibration, shock and high temperatures found in motorsport. With a modular construction and programmable amplifier, this provides a fast delivery time for standard configurations.

The ASH Series of High Performance Pressure Transducers have been designed for high temperature installations in motorsport and automotive applications; ideal for high precision data acquisition or control systems. These transducers can be installed directly onto vehicles, or as part of a test stand or dyno.

Offering a high level of reliability and endurance the ASH is protected against the high vibration, shock and high temperatures found in motorsport. Continuous operation up to 150°C allows for installations in hot zones. With a modular construction and programmable amplifier, this provides a fast delivery time for standard and custom configurations.

Pressure ranges are available between 1.2 to 400 Bar in either Absolute or Sealed Gauge reference. Industry standard 3-wire electrical connections for the Pressure signal allow configuration with most common ECU’s and data logging systems.

The ASM Series of Miniature High Temperature Pressure Transducers have been designed for high temperature installations in demanding motorsport and automotive applications; ideal for high precision data acquisition or control systems. These transducers can be installed directly onto vehicles, or as part of a test stand or dyno.

Offering a high level of reliability and endurance, the ASM Series is protected against the high vibration, shock and high temperatures found in motorsport. With a modular construction and a programmable amplifier, this provides a large stock available of standard parts for fast delivery.

Pressure ranges are available between 1 to 250 Bar in either Absolute or Sealed Gauge reference. Industry standard 3-wire electrical connections allow configuration with most common ECU’s and data logging systems.

The ASMPB Series of Standard Pressure Transducers have been designed for the detection of fluid and air pressures in demanding motorsport and automotive applications; ideal for high precision data acquisition or control systems. These transducers can also be installed directly onto vehicles, or as part of a test stand or dyno.

Offering a high level of reliability and endurance, the ASMPB Series is protected against the high vibration, shock and high temperatures found in motorsport. With a modular construction and a programmable amplifier, this provides a large stock available

of standard parts for fast delivery.

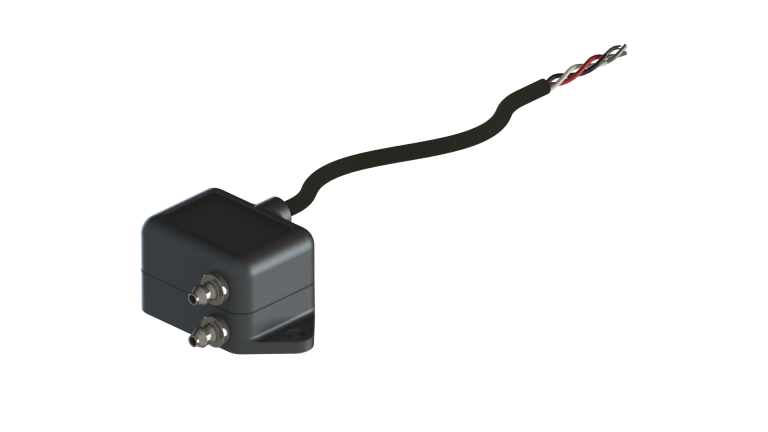

The KAP Series is designed for the measurement of dynamic air/gas pressure on or within a vehicle. When used with a Pitot Tube the transducer measures the differential air pressure which is proportional to air speed. Alternatively the KAP can be connected to pressure tappings on aero surfaces to evaluate aerodynamic performance. These transducers are suitable for use directly onto vehicles or as part of a test stand or dyno. Offering a high level of reliability and endurance, the KAP is protected against the high vibration, shock and high temperatures found in motorsport. Also suitable for wet/wet installations.

With a modular construction and programmable amplifier, this provides a fast delivery time for standard configurations. Pressure ranges are available between 25 to 75 mBar Differential. Industry standard 3-wire electrical connections allow configuration with most common ECU’s and data logging systems.

The KAP Series is race proven and can be found in many race series around the world. Please see our separate datasheet (KAPT) for details of the standard and custom Pitot Tubes that can be supplied.

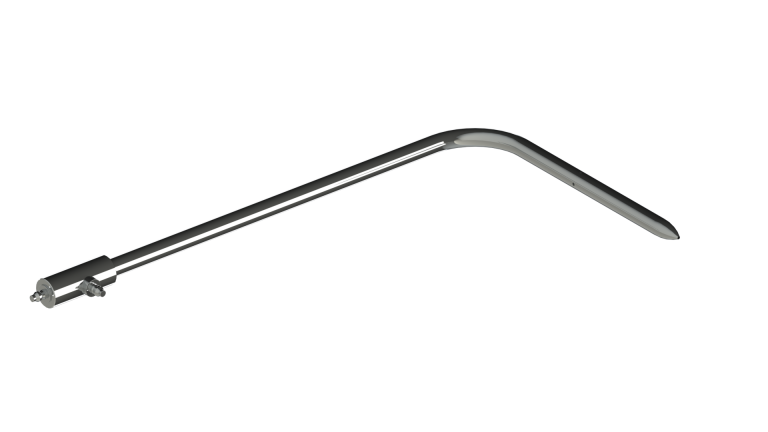

A Pitot Tube is used to measure Speed relative to the surrounding air. The assembly is made up of a pair of concentric tubes; the ellipsoidal nose cone at the tip has a small aperture in the end which is connected to the inner tube whilst an annular ring of holes on the outer tube senses the static/surrounding air pressure.

Therefore by measuring the difference between the air pressure of the inner and outer tubes (please see KA Sensors KAP Differential Pressure Sensor), the speed of the vehicle can be sensed, measured and calculated.

The KAPT Pitot Tube is an in house design and is a manufactured product that is ideally partnered with the KAP Differential Pressure Sensor. Individually or used together they offer a cost effective High Performance solution for Dynamic Pressure Measurements in demanding motorsport and automotive applications; ideal for high precision data acquisition or control systems.

Offering a high level of reliability and endurance the KAPT is protected against the high vibration, shock and high temperatures found in motorsport. The KAPT is also suitable for wet/wet installations.

The ASUH Series of High Performance Sub-Miniature Pressure Transducers have been designed for demanding high temperature installations in precision engineering. The new design utilises miniaturised hybrid components, allowing savings in both size and weight.

This transducer has enhanced performance at elevated temperature and is optimised for extreme installations such as on-engine or transmissions. With a modular construction and programmable amplifier, this provides a fast delivery time for standard and custom configurations.

© 2025 bf1systems ltd. | Registered Company No 2902036 | VAT No. GB 751 0890 38.

Registered Office: Technical Centre, Owen Road, Diss, Norfolk, IP22 4ER, United Kingdom